As we mentioned in our last blog post (check it out here), there are 3 main areas to consider when it comes to reducing noise transmission through a window.

Due to the importance of these 3 elements, we want to take a closer look at them one–by–one. Today we will focus on the first one: the materials used to build a window.

In essence, all the materials that make up your window need to be of good soundproofing quality. If there is one element that is not up to standard it will affect the performance of the whole window unit. This is because sound, like air, will always find the weakest entry point into a space.

Let’s shine a light at the basic building blocks of a window: frame, adhesives and fillers and glazing.

The frame:

The composition of the frame is critical to the overall noise-blocking properties of a window, as it is futile having expensive acoustic glazing if the sound can travel straight through the hollow window frame itself. In older buildings window frames are typically made from timber or mild steel, while those in newer buildings are commonly made from aluminium or PVC.

Timber is a reasonable conductor of sound waves. Traditional timber windows in Singapore are very thin, do not have space for multipoint-locking hardware and can warp due to the humidity which creates cracks and gaps that the noise can travel through. Overall, timber windows in Singapore are usually not soundproof.

Mild hollow steel frames are not suitable for soundproofing as the noise travels straight through steel which it is a good conductor of sound and heat.

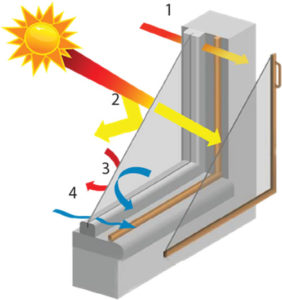

Aluminium frames are locally the most popular choice, however, the majority in the market are made of thin, hollow aluminium. This helps the frames to be lighter in weight and is cost-efficient; however single chamber, hollow aluminium sections can transmit the noise straight through the frame. Multi-chamber sections, or even better thermally broken aluminium frames (the frame consists of two separate parts connected by a polyamide or polyurethane spacer that blocks heat and sound transmission from the outside to the inside), can be a great choice for soundproof windows.

PVC or uPVC window frames made from unplasticised polyvinyl chloride (Rigid Plastic) are very popular in Europe and the USA. Most uPVC window frames have multiple chambers and an inserted steel core which does not allow the sound to travel through, and also prevents warping due to weather changes. They are the top choice for soundproof windows; however, quality uPVC windows tend to be more expensive in Singapore and there are some restrictions for the use in high rise buildings.

For our add-on soundproofing in the Magnetite system, the frames are made from foam-filled uPVC. This means that the whole frame consists of sound dampening foam to increase the ability to absorb noise more effectively.

Adhesives and Fillers:

This element has two parts to take into consideration: The seals holding the glazing in the frame, and the fillers and adhesives (used to fill the area in between the wall and the window frame).

Let’s start with the seals holding the glazing in the frame.

In days gone by the glass was held in place with window putty; this needed constant maintenance and repair, and offered almost zero soundproofing qualities. In modern frames putty has been replaced by rubber seals to hold the glass in place. A good soundproofing seal will not pull away from the glass if you pull on it and should remain in place all around the window. It’s a good idea to inspect these seals every 6 months or so for any sign of wear-and-tear.

The filler used when the window is installed is also very important. If there are any unseen gaps between the wall and the window it will allow air and noise to travel inside, even if there are microscopic cracks. Specialised acoustic caulks and fillers are used to ensure that there are no gaps between the window and the wall; ideally they should be flexible to expand and contract (as the weather changes) without cracking.

Glass/Glazing:

It is commonly believed that by adding thicker glass into your existing frame the window will become more effective in reducing noise. In reality, it often makes the problem worse. The existing frame, and the hardware used, was constructed for a certain glass weight in mind. If you double that weight, your window sash will probably sag, straining under the extra weight. Worst case, the existing frame could buckle under the added weight of the glass or the heavier glass load could drop down in the frame and become loose and fall out.

Glass is a rigid material and so does allow sound to travel through quite easily. The popular 3mm thick, tempered, safety window glass does not offer much in the way of noise reduction.

If you are able to change your entire window, a good and cost–effective option can be laminated glass. Laminated glass consists of two glass panes with an interlayer in between them. The plastic interlayer provides a degree of sound absorption and reduces the sound vibration coming through the glass. It looks like a single pane of glass and is generally cheaper than double glazing. Acoustic glazing means that the interlayer has special sound dampening properties and comes at a cost premium.

Double and triple glazing does help compared to normal single glazing but the main intention behind their use is for cold or heat reduction, not sound. If you are considering double or triple glazing, choose a unit with different glass thicknesses and an air-gap of at least 20mm between the two panes of glass (although for soundproofing result, you’ll want at least 25mm airgap but we’ll speak about that in a later blog post).

If you are not able to replace your windows, your best option is to install secondary glazing on the inside of your existing window with an air gap of 100mm between the existing and new glazing. The Magnetite system offers add-on units which attach to the interior side of your existing window cavity and uses 10mm optical grade acrylic instead of glass, offering great sound reduction qualities.

To summarise, there is no simple answer to which window is the best for soundproofing, you really must look into the details.

Generally, one needs to look for a uPVC or aluminium window frame that is not hollow, and which is strong enough to carry the load of thicker glass. It should have a strong rubber seal to hold the glass in place and the gaps between the wall and the window should be filled with acoustic caulk or foam when installed to prevent sound leakage through cracks. The glass in your window should ideally consist of two panes of different thicknesses, either laminated together or with a minimum airgap of between 20mm between the two.

We highly recommend you ask your window provider for an acoustic test for the entire window system they are trying to sell you – not just the glass.