Our last blog post explained how important it is that all components of a window are made from soundproof material (read it here). All these parts need to work together as a system to perform as desired; a system that also has to include the next important element, which we will explore today: All-round tight seals.

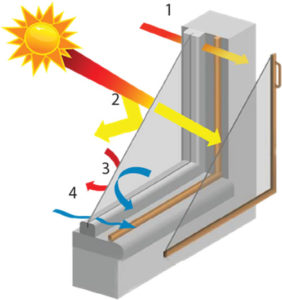

A tight seal is essential to ensure that no sound can come through. Think of the seal on the door of your fridge – if there is a small gap, or if the frame is bent, then the cold air flows out. This is exactly the same for soundproof windows – a small opening or area where the seal has not compressed sufficiently will allow the sound to enter (or exit). Sound travels through air and if the air can seep in through an opening then so can the sound.

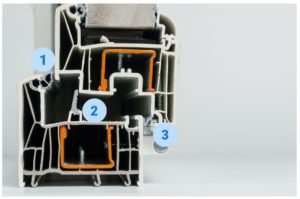

Most people think of the rubber gaskets fixed around a window when we speak of “sealing the window” and yes, they are an important part of it. However, the mechanical squeezing of these gaskets onto a flat surface to seal the window and to create a blockage for air and sound is essential for a good soundproofing result. For that, something has to press the window sash to the window frame. This is the job of the window hardware which provides locking points.

In Singapore, most windows only have a single locking point in the middle of the window where the handle is. This means compression only happens at that point. At the top and bottom of the window nothing presses sash and frame together and this is where we can often find gaps that let noise in.

Ideally, we want to have locking points on all 4 sides, like European style inward opening windows have, so the seal can be compressed on each side. For push-out windows, look out for a minimum of 3 locking points so that at least the middle, the top and bottom of the window sash pushes onto the seals. For this to be possible the window profile usually has to allow for a channel that hardware runs in, called a groove.

The term to ask your window provider for is “multi-point locking”.

This is one of the easiest ways to check if a window that is offered to you as “soundproof” is the real deal. Check the profile structure for a groove and for multi-point locking.

Once we have multi-point locking compressing our seals, we need to ensure that our gaskets are of good tensile strength and should be temperature and weather resistant so as not to rot, warp or crack. Rubber is the most commonly used material as it is both flexible and weather resistant. Brush seals offer little in terms of soundproofing as the sound can move straight through the bristles (like the gaps in your toothbrush). These seals also need to fit properly into the profiles so that they fit snug with the edges of the window frame and stay in place – the entire system needs to be designed to work perfectly together.

Lastly, we want to check how many seals the window has. Standard windows usually have only 1 seal on the hinged part of the window, with another one on the frame in the wall, which is often a brush seal to reduce the knocking noise when closing the window. A good soundproof window will have at least 3 seals – all made from rubber.

To summarize, look for a window with multipoint locking with 3 rubber seals to ensure that your window has an all-round tight seal. If you cannot change your window, the Magnetite Noise Shields offer a full 4- sided magnetic seal to achieve up to 70% noise reduction, check it out here.

Next month we will look at the third pillar of a soundproof window: The Air Gap. Meantime, you can check out our window soundproofing solution here.